Jute Yarn

from fibre to yarn - carding, drawing, spinning

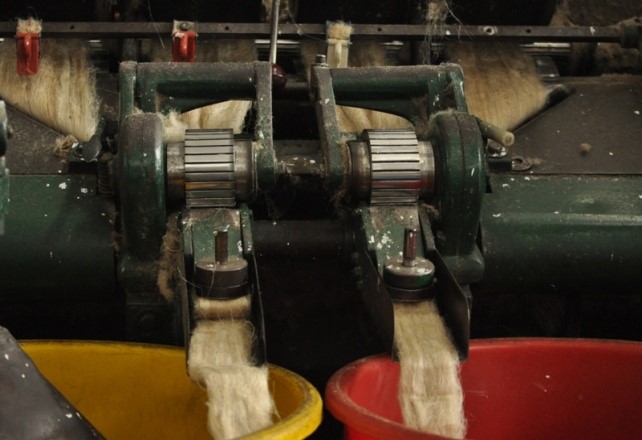

Jute drawing, carding and spinning

After piling, the Morah bales are reopened and the filaments carded several times to comb them parallel, then drawn to produce an average overlap into a ribbon-like slither ready for twisting. The width of the slither will determine the final twisted yarn parameters: diameter and weight.

Yarn weights are measured in the Jute Count, a British colonial imperial measurement in pounds of 14,400 yards of yarn quantity.

Optimum yarn twist, balancing coherence and obliquity is critical to strength. Loose twist is weaker, because slippage under load may cause catastrophic tear. Tight compromises linear orientation, causing shear.

Lighter, thinner yarns may be subsequently twisted together twice (2–ply), 3–times (3-ply), etc. This may add strength, but also adds another twist dynamic to be balanced counter to strands (in rope), and produces knurling (bumps or knobs on the surface of the final product).

In certain applications, a final coating may be applied before the yarn is wound on a bobbin. When used, polyvinyl alcohol or vegetable starches are common.

Image above: jute spinning